A new European flexible heatshield prototype has born.

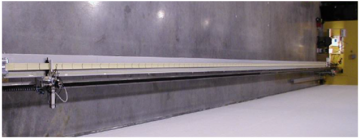

The 1st loop testing campaign for the 2.5 meters prototype of the EFESTO inflatable heatshield for space applications was successfully performed at TRLA premises in Canada.

The results are in line with the expectations and provide evidence of a good status toward the manufacturing of the final Demonstrator Test Article supposed to undergo a 2nd Loop testing campaign in CIRA by next Spring.

The H2020 EFESTO project aims to develop inflatable heatshields for planetary exploration and reentry vehicles, allowing larger decelerating surfaces to be folded and stored within the launcher's fairing constraints, increasing the exploration capabilities and allowing larger payloads to be landed.

Within the EFESTO project, multiple aspects of inflatable structures physics are planned to be addressed by test. Test activities include research on materials and ground verification to feed the model’s validation and extrapolation to flight.

Two main activities are carried out:

- 1st Loop Session: test at material assembly level or Inflatable Structure fabrics testing

- The Tendons, Carrier Fabrics, and Gas Bladder

- 2nd Loop Session: test at the system level or ground demonstration tests on a breadboard

The 1st Loop testing campaign took place at TRLA premises, involved as a supplier of the Inflatable Structure in the frame of the subcontracting deal between CIRA and the Italian SME ALI srl.

During the tendon tests, the challenge in obtaining the appropriate density, circumference and diameter values lies in the fact that all braided products feature highly variable dimensions in their relaxed state-dimensions which are conspicuously smaller than dimensions obtained under even light loads.

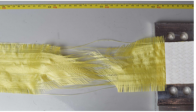

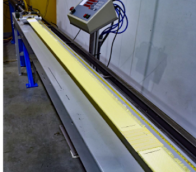

The test is set at TRLA for the characterization of 25-meter pressure restraint straps.

25-meter pressure restraint straps

25-meter pressure restraint straps

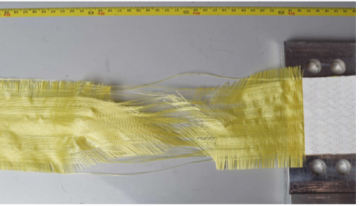

Kevlar® Carrier fabric failure.

Kevlar® Carrier fabric failure.

In the carrier fabrics tests, fibre material constituents of woven fabric are chosen based on their ability to perform specific tasks, therefore optimum performance demands minimum fibre trauma in construction of the woven product.

The EFESTO Breadboard’s Kevlar® Carrier fabric was tested by TRLA, where the typical break status is shown.

Finally, the gas bladder is chosen among TRLA’s proprietary bladder film on which stress-strain tests are carried out.

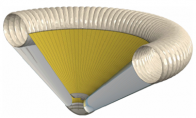

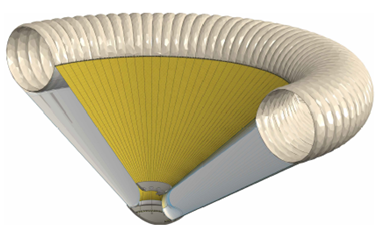

The three elements are integrated into a 2.5-meter diameter Dual Body IAD prototype by Thin Red Line Aerospace.

The aim is to develop broader and more detailed insights regarding the operational possibilities presented by the Dual Body architecture. The prototype is exactly the same 60-degree sphere-cone, high fidelity, and building materials as the EFESTO Breadboard, and it will allow the exploration of packing configurations.

EFESTO aims to develop inflatable heatshields, allowing larger decelerating surfaces to be folded and stored within the launcher's fairing constraints, increasing the exploration capabilities and allowing larger payloads to be landed.

The project responds to the call H2020-SPACE-11-TEC-2018 for “Generic Space Technologies” and has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 821801.